- HOME

- Our Business

- Recycling Machines Business

- Shredder Plant

Plant Layout / Pre-shredder / Shredder

Morita Shredder Plant paves the way for recycling of waste materials.

Crushes and sorts bulk scrap to recover high purity, high density iron and non-ferrous metals

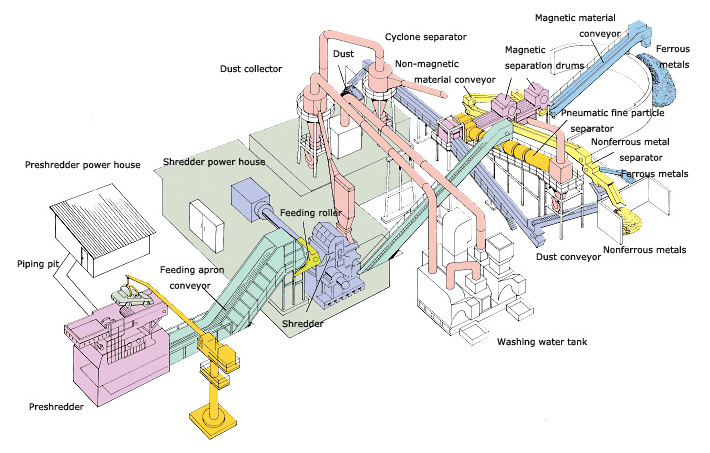

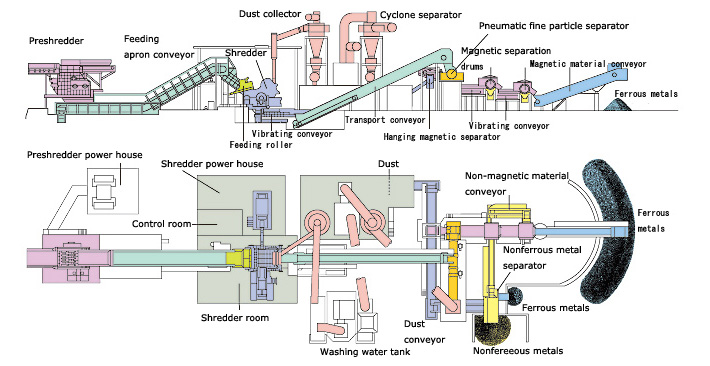

The Morita Environmental Tech's shredder plant crushes and sorts scrap cars, city garbage, old home appliances, industrial waste and other bulk waste to efficiently recover high purity, high density and uniform granular iron and nonferrous metals. The plant can even accept steel turnings and bushellings. Environmental protection and safety measures have been also taken into account in the plant design. Morita Environmental Tech offers the optimal equipment, throughput and plant layout suited to your needs.

Processing Flow

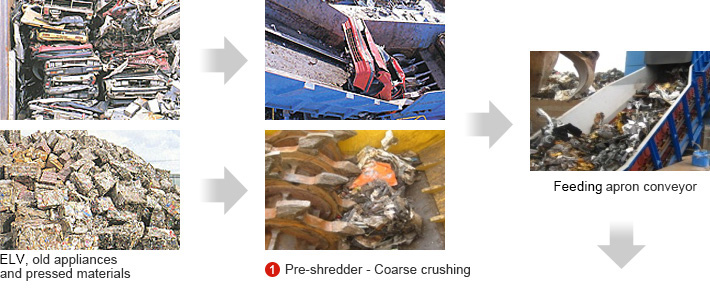

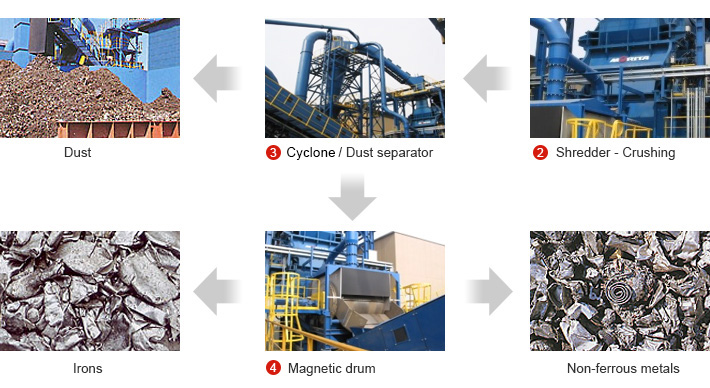

- Bulk waste such as scrap cars, city garbage, old home appliances and industrial waste is first roughly-crushed by a "pre-shredder".

- The crushed scrap is thrown into a "shredder" by "feeding rollers" sequentially and smoothly and then further crushed into fine sized pieces.

- These crashed pieces are separated into iron and non-ferrous metals & dust. The iron is recovered as it is.

- The mixture of non-ferrous metals and dust are separated into non-ferrous metals and dust by an "cyclone" and a "non-ferrous metal separator".

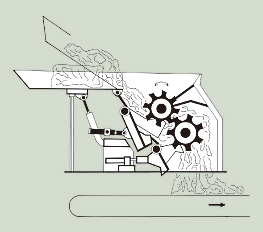

Pre-shredder

Roughly-crushes ELVs and pressed car bodies at a gulp

MODEL :

TN-200 / TN-300 / TN-450 / TN-600 / TN-800

The pre-shredder is a pretreatment shredder to ensure efficient and safe operation of the shredder.

By roughly-crushing various scraps in advance, the pre-shredder backs up the shredder operation.

- Allows the shredder to easily handle pressed scrap bodies and vehicles with wheels and engines.

- Helps stabilize the operating load of the shredder. Improves the throughput. Reduces the power consumption.

- Ensures longer life of shredder consumables including hammers and liners.

- Provides explosion prevention and other safety measures.

Mechanical features of the pre-shredder

- Bulk waste such as scrap cars, city garbage, old home appliances and industrial waste is first roughly-crushed by a "pre-shredder".

- Adjusting the compressing blades will easily change the throughput and crushing size.

- The mechanism is applied with less impact since a hydraulic pump and a torque motor is used for driving.

- Stably operates with automatic control.

Product Movie

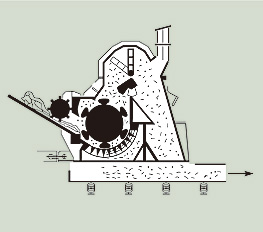

Shredder

Crushing into uniform granules

MODEL :

TH-300 / TH-500 / TH-750 / TH-1000 / TH-1250 / TH-1500 / TH-2000 / TH-3500

Scrap roughly-crushed by the pre-shredder is further crushed into fine granules by this high-performance shredder.

Features of the shredder body

- The shredder body uses special steel liner on its internal surface, ensuring outstanding durability.

- The shredder body is equipped with a hammer/pin removal device. Hammers and pins can easily be changed.

- The body casing can be widely opened with a hydraulic cylinder, ensuring easy maintenance and inspection.

- The lower damper also serves as an uncrushable material outlet, minimizing internal damage caused by uncrushables.

- Paint, oil and dust flakes or sheds off scrap during crushing process, making it possible to recover high purity iron.

- The granule size of product can be freely, easily adjusted with the damper system interlocked with the feeding rollers.